Opening the car to American ingenuity

Car enthusiasts rejoice!

Car enthusiasts rejoice!

Some environmentalists believe that if you invest in and develop alternative replacement fuels (e.g., ethanol, methanol, natural gas, etc.) innovation and investment with respect to the development of fuel from renewables will diminish significantly. They believe it will take much longer to secure a sustainable environment for America.

Some environmentalists believe that if you invest in and develop alternative replacement fuels (e.g., ethanol, methanol, natural gas, etc.) innovation and investment with respect to the development of fuel from renewables will diminish significantly. They believe it will take much longer to secure a sustainable environment for America.

Some of my best friends are environmentalists. Most times, I share their views. I clearly share their views about the negative impact of gasoline on the environment and GHG emissions.

I am proud of my environmental credentials and my best friends. But fair is fair — there is historical and current evidence that environmental critics are often using hyperbole and exaggeration inimical to the public interest. At this juncture in the nation’s history, the development of a comprehensive strategy linking increased use of alternative replacement fuels to the development and increased use of renewables is feasible and of critical importance to the quality of the environment, the incomes of the consumer, the economy of the nation, and reduced dependence on imported oil.

There you go again say the critics. Where’s the beef? And is it kosher?

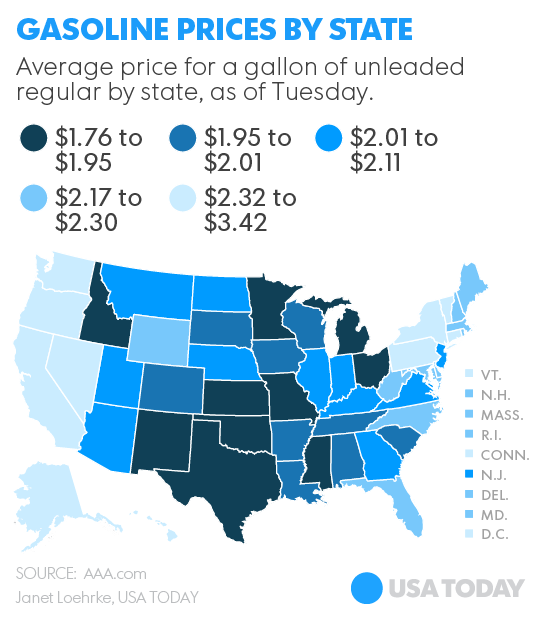

Gasoline prices are at their lowest in years. Today’s prices convert gasoline — based on prices six months ago, a year ago, two years ago — into, in effect, what many call a new product. But is it akin to the results of a disruptive technology? Gas at $3 to near $5 a gallon is different, particularly for those who live at the margin in society. Yet, while there are anecdotes suggesting that low gas prices have muted incentives and desire for alternative fuels, the phenomena will likely be temporary. Evidence indicates that new ethanol producers (e.g., corn growers who have begun to blend their products or ethanol producers who sell directly to retailers) have entered the market, hoping to keep ethanol costs visibly below gasoline. Other blenders appear to be using a new concoction of gasoline — assumedly free of chemical supplements and cheaper than conventional gasoline — to lower the cost of ethanol blends like E85.

Perhaps as important, apparently many ethanol producers, blenders and suppliers view the decline in gas prices as temporary. Getting used to low prices at the gas pump, some surmise, will drive the popularity of alternative replacement fuels as soon as gasoline, as is likely, begins the return to higher prices. Smart investors (who have some staying power), using a version of Pascal’s religious bet, will consider sticking with replacement fuels and will push to open up local, gas-only markets. The odds seem reasonable.

Now amidst the falling price of gasoline, General Motors did something many experts would not have predicted recently. Despite gas being at under $2 in many areas of the nation and still continuing to decrease, GM, with a flourish, announced plans, according to EPIC (Energy Policy Information Agency), to “release its first mass-market battery electric vehicle. The Chevy Bolt…will have a reported 200 mile range and a purchase price that is over $10,000 below the current asking price of the Volt.It will be about $30,000 after federal EV tax incentives. Historically, although they were often startups, the recent behavior of General Motor concerning electric vehicles was reflected in the early pharmaceutical industry, in the medical device industry, and yes, even in the automobile industry etc.

GM’s Bolt is the company’s biggest bet on electric innovation to date. To get to the Bolt, GM researched Tesla and made a $240 million investment in one of its transmissions plan.

Maybe not as media visible as GM’s announcement, Blume Distillation LLC just doubled its Series B capitalization with a million-dollar capital infusion from a clean tech seed and venture capital fund. Tom Harvey, its vice president, indicated Blume’s Distillation system can be flexibly designed and sized to feedstock availability, anywhere from 250,000 gallons per year to 5 MMgy. According to Harvey, the system is focused on carbohydrate and sugar waste streams from bottling plants, food processors and organic streams from landfill operations, as well as purpose-grown crops.

The relatively rapid fall in gas prices does not mean the end of efforts to increase use of alternative replacement fuels or renewables. Price declines are not to be confused with disruptive technology. Despite perceptions, no real changes in product occurred. Gas is still basically gas. The change in prices relates to the increased production capacity generated by fracking, falling global and U.S. demand, the increasing value of the dollar, the desire of the Saudis to secure increased market share and the assumed unwillingness of U.S. producers to give up market share.

Investment and innovation will continue with respect to alcohol-based alternative replacement and renewable fuels. Increasing research in and development of both should be part of an energetic public and private sector’s response to the need for a new coordinated fuel strategy. Making them compete in a win-lose situation is unnecessary. Indeed, the recent expanded realization by environmentalists critical of alternative replacement fuels that the choices are not “either/or” but are “when/how much/by whom,” suggesting the creation of a broad coalition of environmental, business and public sector leaders concerned with improving the environment, America’s security and the economy. The new coalition would be buttressed by the fact that Americans, now getting used to low gas prices, will, when prices rise (as they will), look at cheaper alternative replacement fuels more favorably than in the past, and may provide increasing political support for an even playing field in the marketplace and within Congress. It would also be buttressed by the fact that increasing numbers of Americans understand that waiting for renewable fuels able to meet broad market appeal and an array of household incomes could be a long wait and could negatively affect national objectives concerning the health and well-being of all Americans. Even if renewable fuels significantly expand their market penetration, their impact will be marginal, in light of the numbers of older internal combustion cars now in existence. Let’s move beyond a win-lose “muddling through” set of inconsistent policies and behavior concerning alternative replacement fuels and renewables and develop an overall coordinated approach linking the two. Isaiah was not an environmentalist, a businessman nor an academic. But his admonition to us all to come and reason together stands tall today.

Clean-energy entrepreneur Jigar Shah makes a case for investing in technology that will help the United States end its dependence on foreign oil, instead of just talking about it.

In a post for Unreasonable.is, he laments the lost opportunities: The U.S. has reduced its oil imports by 15 percent over the last two years as the country has ramped up its own oil production. But we “still imported an average 7.4 million barrels of crude oil per day during the first nine months of 2014—at a cost of more than $240 billion.”

Increasing fuel-economy standards in vehicles has gotten us only partway toward oil independence (he notes that as miles-per-gallon have vastly increased since the 1970s, so too has the weight of the cars Americans increasingly prefer: the large SUVs). He adds:

The predicted increase in oil drilling in the U.S. and Canada will get us even closer. But no matter how we slice the data, we will still depend on imported oil. Domestic drilling and fuel standards are not enough—we need fuel choice.

Shah writes that replacement fuels like methanol, hydrogen, electricity and other renewables are cheaper than gasoline or diesel.

However, the Government has not systematically put a plan in place to give American’s access to these fuels at local refueling stations. In fact, the Government regulations in place today make it difficult to add these fuel choices.

In addition to alternative fuels, vehicle efficiency technologies offer another off-ramp towards oil independence. With only one out of every seven gallons of gas being used to move the car forward, it is time to stop waging war in the Middle East and start the war against vehicle inefficiency.

He lists some interesting innovations for increasing fuel efficiency. Check them out.

To read the newspapers these days, you’d think that all the innovation in energy is involved in bringing down the cost of solar panels or building even bigger blades for windmills. But innovation still continues apace in oil and gas, both in pulling them out of the ground and in finding new ways to use them.

“We haven’t been giving the big oil companies enough credit,” said Dominic Basulto in The Washington Post. “ Sure, we may see their print ads or watch as they tout their accomplishments on TV, but deep down, many of us believe that the brightest minds have moved on to something new in energy innovation. But that’s not true.”

That’s important because if we’re going to use our abundant natural gas supplies to wean ourselves off of foreign oil, we’re going to have to be sure the current superabundance of natural gas isn’t just a flash in the pan. Moreover, we’re going to need innovation in making the transition to methane-based liquid alcohol fuels easier as well.

As most people have heard by now, even our best technologies can’t extract more than about 10-20% out of an oil or gas reservoir from the earth. Simply doubling that rate would give us access to huge, new quantities of domestic fuels.

There’s also a concern that fracking wells will have a much shorter lifespan than traditional gas and oil wells. Then there’s all that natural gas being flared off in the Bakken. Ending that conspicuous form of waste will require some new technology.

All these problems are being tackled through innovation, however, and that’s what Basulto is talking about.

Although everybody knows about fracking — the technology of forcing sand and water into the rock to break it up — few realize that the real novelty that makes up the current upturn in production possible is horizontal drilling, which allows access to entire geological strata without making the territory look like a pincushion.

“Today, drilling rigs are so good that they can punch holes in the earth that are two miles deep, turn the drill bit 90 degrees, drill another two miles horizontally, and arrive within a few inches of the target,” said Robert Bryce, author of “Smaller, Faster, Lighter, Denser, Cheaper,” a book about innovation in the energy industry. But horizontal drilling hasn’t stood still. ExxonMobil has developed an “extended reach” technology that can push outward several miles further deep in the earth. “Extended reach reduces our environmental footprint and in offshore applications will limit our presence in the marine environment,” says the company’s website. It may have been developments like this that prompted President Obama to give a green light to exploration off the Atlantic Coast from Delaware to Florida last month.

The same innovations are occurring with natural gas fracking. Innovators have made an improvement called “sleeve technology” that surrounds the drill bit and allows highly accurate placement of stimulation treatments. The result is that wells can be drilled twice as fast as a few years ago, at a lower cost. With increased precision in both drilling and fracturing, wells are being made more productive as well. Erika Johnsen on Hot Air said, “Data from the Energy Information Administration’s Drilling and Production Report shows that a Marcellus Shale well completed by a rig in April 2014 can be expected to yield over 6 million cubic feet of natural gas per day (Mcf/d) more than a well completed by that rig in that formation in 2007.” That’s a huge improvement in the space of seven short years.

All this is good news for the effort of substituting natural gas-based ethanol or methanol for foreign oil in our cars. After all, one of the fundamental considerations is that there will be enough natural gas around to keep the price reasonable. With so many competing proposals for employing natural gas — electrical generation, the industrial revival, LNG exports, etc. — it’s crucial that we keep expanding production.

So it’s encouraging to hear the news from Clean Energy Fuels, T. Boone Pickens’ baby, which has been building a “CNG Highway” across the country to service long-haul tractor-trailers. CEF has just completed the first leg of this nationwide network, connecting Los Angeles and Houston.

But much of the nation still lies outside the reach of natural gas pipelines and CEF is figuring out a way to serve them, as well. Last month the company opened a filling station in Pembroke, New Hampshire that will be served by a “virtual pipeline” of high-tech tractor-trailers making round-the-clock deliveries. This will allow the station to pump 10 million gasoline-gallon-equivalents (GGE), twice the volume of CEF’s largest existing station. More important, it will open up large areas of the country that have not had access to CNG. This natural gas-based substitute will sell for 30% less than gasoline.

Technology never stands still. Sometimes it forces us to give up things that have become familiar or even seemingly permanent. But as Robert Bryce said, the new technology is usually “faster, smaller, lighter, denser and cheaper.” And in the case of methane-based liquid fuels, it will mean freeing ourselves from foreign oil as well.

Researchers at the University of California, Riverside, have come up with a magic ingredient that may improve the performance of lithium-ion batteries by a factor of three. It’s common beach sand.

In 1962, German researcher Hanns-Peter Boehm suggested the versatile carbon atom, which can form long chains, might be configured into a chicken-wire pattern to create a stable molecule one atom thick.

The idea remained a theoretical construct without even a name until 1987, when researchers started calling it “graphene.” Basically, graphene is two-dimensional graphite, the pure carbon material that makes up “lead” pencils. The term was also used to describe the carbon nanotubes that were beginning to attract attention for their ultra-solid properties. For a while there was talk of elevators reaching up into space until it became clear that creating nanotubes without impurities that degrade their properties was currently out of the reach of mass production.

Then in 2004, Andre Geim and Kostya Novoselov, two researchers at The University of Manchester, came up with something a little more prosaic. They applied Scotch tape – yes, ordinary Scotch tape – to pure graphite and found they could peel off the single layer of carbon in the chicken-wire pattern that Boehm had described. They called this substance “graphene” and were awarded the Nobel Prize in 2010.

The discovery of single-layer graphene has set off a stampede into research of its properties. Carbon is, after all, a versatile element, the basic building block of life that can also be packed into a material as hard as a diamond, which is also pure carbon. When stretched out into lattices a million times thinner than a human hair, however, it has the following remarkable properties:

In short, graphene is now being touted as “material of the 21st century,” the substance that could bring us into an entirely new world of consumer products, such as cell phones that could be sewn into our clothes.

All this still remained somewhat theoretical, since no one had been able to produce graphene in dimensions larger than single tiny crystals. When these crystals were joined together, they lost most of their properties. Two weeks ago, however, Samsung announced that it has been able to grow a graphene crystal to the size of a wafer, somewhat on the same dimensions as the silicon wafers that produce computer chips. Thus, the first step toward a new world of electronics may be upon us. Graphene cannot be used as a semiconductor, since it is always “on” in conducing electricity, but combined with other substances it may be able to replace silicon, which is many researches believe is currently reaching its physical limits.

So what does this mean for the world of transportation, where we are always looking for new ways to construct automobiles and find alternative power sources to substitute for our gas tanks? Well, plenty.

Most obvious is the possibility of making cars out of much lighter-weight materials to reduce the power burden on engines. Chinese researchers recently came up with a graphene aerogel that is seven times lighter than air. A layer spread across 28 football fields would weigh only one ounce and a cubic inch of the material would balance on a blade of grass. All this would occur while it still retained its 300-times-stronger-than-steel properties. Graphene itself would not be used to construct cars, but it could be layered with other materials.

But the most promising aspect of graphene may be in the improvement of batteries. Lithium-ion batteries achieve an energy density of 200 Watt-hours-per-kilogram, which is five times the 40-Wh/k density of traditionally lead-acid batteries. That has won it the prime role in consumer electronics. But Li-ion batteries degrade over time, which is not a problem for a cell phone, but becomes prohibitive when the battery must undergo more than 1,000 charge cycles and is half the price of the car.

Lithium-sulfur batteries have long been thought to hold promise but they, too, deteriorate quickly, sometimes after only a few dozen charges. But recently, researchers at Lawrence Berkeley Labs in California modified a lithium sulfur battery by adding sandwiched layers of a graphene. The result is a battery that achieves 400 Wh/k – double the density of plain lithium-ion – and has gone through 1,500 charging cycles without deterioration. This would give an electric car a range of more than 300 miles, which is in the lower range of what can be achieved with the internal combustion engine.

And so the effort to improve electric vehicles is moving forward, sometimes on things coming out of left field. If graphene really proves to be a miracle substance, look for Elon Musk to be discussing its wonders as he prepares to build that “megafactory” that is supposed to produce lithium-ion batteries capable of powering an affordable new version of the Tesla.

Elon Musk doesn’t mind making comparisons between himself and Henry Ford. Others are doing it as well.

In announcing his plans for a “Gigafactory” to manufacture batteries for a fleet of 500,000 Teslas, Musk said it would be like Ford opening his famous River Rouge plant, the move that signaled the birth of mass production.

The founder of PayPal and current titular leader of Silicon Valley (now that Steve Jobs is gone), Musk is not one for small measures. The factory he is now dangling before four western states would produce more lithium-ion batteries than are now being produced in the entire world. And that’s not all. He’s designing his new operation to mesh with another cutting-edge, non-fossil-fuel energy technology – solar storage. His partner will be SolarCity (where Musk sits on the board), run by his cousin Lyndon Rive. Together they are looking beyond mere automobile propulsion and are envisioning a world where all this solar and wind energy stuff comes true.

So, is Musk a modern-day Prometheus, bringing the fire to propel an entirely new transportation system? Or, as many critics charge, is he just conning investors onto a leaky vessel that is eventually going to crash upon the shores of reality? As the saying goes, we report, you decide.

One investor that is already showing some qualms is Panasonic, which already supplies Tesla with all its batteries and would presumably help the company fill the gap between the $2 billion it just raised from a convertible-bond offering and the $5 billion needed to build the plant. “Our approach is to make investments step by step,” Panasonic President Kazuhiro Tsuga told reporters at a briefing in Tokyo last week. “Elon plans to produce more affordable models besides [the] Model S, and I understand his thinking and would like to cooperate as much as we can. But the investment risk is definitely larger.” Of course, this is Japan, where “the nail that sticks out gets hammered down.” Corporate executives are not known for sticking their necks out.

Another possible investor is Apple, which has mountains of cash and, at least under Steve Jobs, was always willing to jump into some new field – music, cell phones – to try to set it straight. This is a little more ambitious than the Lisa or the iPod and Jobs is no longer around to steer the ship, but Apple and Musk officials held a meeting last spring that stirred a lot of talk about a possible merger. A much more likely scenario, according to several commentators, is that Apple would become a major player in the Gigafactory.

And a Gigafactory it will be. Consider this. The three largest battery factories in the country right now are:

1) The LG Chem factory in Holland, Mich. is 600,000 square feet, employs 125 people and produces 1 gigawatt hour (GWH) of battery output per year.

2) The Nissan factory in Smyrna, Tenn. is a 475,000 square-foot facility with 300 employees puts out 4.8 GWH per year.

3) A123 Systems’ battery factory in Livonia, Mich. is 291,000 square feet, employs 400 people and produces 0.6 GWH per year.

Both LG and Nissan received stimulus grants from the Department of Energy, built to overcapacity and are now operating part-time.

Now here’s what Musk is proposing. His Gigafactory would cover 10 million square feet, employ 6,500 people and produce 35 GWH per year of battery power. Basically, Musk’s operation is going to be ten times better anything ever built before, at a time that most of what exists isn’t even running fulltime. Does that sound like something of Henry-Ford proportions? Similar to Ford’s $5 a day wages, perhaps?

There are, of course, people who think all of this is crazy. In the Wall Street Journal blog, “Will Tesla’s $5 Billion Gigafactory Make a Battery Nobody Else Wants?,” columnist Mike Ramsey expresses skepticism over whether Tesla’s strategy of using larger numbers of smaller lithium-ion is the right approach. “Every other carmaker is using far fewer, much larger batteries,” he wrote. “Tesla’s methodology – incorrectly derided in its early days as simply using laptop batteries — has allowed it to get consumer electronics prices for batteries while companies like General Motors Co. and Nissan Motor Co. work to drive down costs without the full benefits of scale. Despite this ability to lower costs, no other company is following Tesla’s lead. Indeed, in speaking with numerous battery experts at the International Battery Seminar and Exhibit in Ft. Lauderdale a few weeks ago, they said that the larger cells would eventually prove to be as cost effective, and have better safety and durability. This offers a reason why other automakers haven’t gone down the same path.

But Musk has managed to produce a car that has a range of 200 miles, while the Leaf has a range of 85 miles and the Chevy Spark barely makes 82. Musk must be doing something right. And with Texas, Arizona, Nevada and New Mexico all vying to be the site of the Gigafactory, it’s more than likely that the winning state will be kicking in something as well. So, the factory seems likely to get built, even on the scheduled 2017 rollout that Tesla has projected.

At that point, Musk will have the capacity to produce batteries to go in 500,000 editions of the Tesla Model E, which he says will sell for $35,000. Sales of the $100,000 Model S were 22,000 last year. Does this guy think big or what?

To date, Silicon Valley doesn’t have a terribly good record on energy projects. Since Kleiner Perkins Caufield & Byers fell under Al Gore’s spell in 2006, its earnings have been virtually flat and the firm is now edging away from solar and wind investments. Venture capitalist Vinod Khosla’s spotty record in renewables was also the subject of a recent 60 Minutes segment. But, as venture capitalists say, it only takes one big success to make up for all the failures.

Will Tesla’s Model E be the revolutionary technology that, at last, starts making a dent in oil’s grip on the transportation sector? At least one investor has faith. “I’d rather leave all my money to Elon Musk that give it to charity,” was the recent evaluation of multi-billionaire Google founder Larry Page.